Journal Contents

Robert Erskine^s letters of 1770 about the British iron and steel industry

Carol Siri Johnson

Pages 75-97

In 1770, the engineer Robert Erskine toured England, Wales and Scotland to collect knowledge about the iron industry. During this tour, he wrote a series of letters detailing the materials, processes and products that he saw. He described blast furnaces, blowing engines, forges, foundries and casting, and steel works. Erskine brought these letters with him to America in 1771, where he had been employed to manage an ironworks begun by Peter Hasenclever in 1764. The introduction includes a brief biography of Erskine and a description of his tour and correspondence and is followed by a transcription of the letters.

Overspun strings from 18th- and 19th-century English square pianos

Martha Goodway

Pages 98-102

Analyses of overspun strings identified the base wire as yellow brass of the maximum composition achievable by the traditional process of cementation, but the red wire wrapped around the 18th-century samples differed from that of the 19th-century wire in two respects: the overspinning in the 18th-century samples was silvered and contained only 1.4% zinc, an amount adequate to deoxidize copper but not enough to strengthen it. The 19th-century wire was not silvered but contained 6% zinc, allowing the wrapping to take a permanent set. It is proposed that the silvering on the I8th-century samples may not be simply decorative but a practical means of maintaining mechanical contact between the two wires.

Puddling: a metallurgical perspective

Merton C Flemings and David V Ragone

Pages 103-108

Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different in terms of the key chemical reactions involved, the thermal behaviour of the melt, the speed of the process and the quality and consistency of the resulting product. In this paper we examine wet puddling from a metallurgical perspective and express our respect for those master puddlers who could control such a complex process with little other than their senses to guide them. Concluding remarks relate to the final years of wrought iron production in Great Britain and the United States.

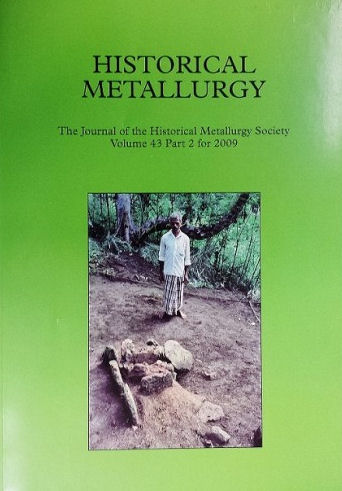

In the footsteps of Ananda Coomaraswamy: Veralugasmankada and the archaeology and oral history of traditional iron smelting in Sri Lanka

G Juleff, P T Craddock and T Malim with contributions by I C Freestone and C R Cartwright

Pages 109-134

Two well-preserved, bellows-driven, shaft furnaces are representative of a traditional, village-based iron-smelting technology that survived into the early 20th century. The excavation data is one component of the record of this technology, which is supplemented by the illustrated eye-witness account by Ananda Coomaraswamy, and also by more recent interviews with the last local inhabitants with first-hand experience and memory of the process itself and the craftsmen involved. These strands of evidence are brought together to give a near-complete description of a bloomery process that has parallels on several continents and the potential to inform the interpretation of many less-complete records.

![[Test] The Historical Metallurgy Society](https://test.historicalmetallurgy.org/wp-content/uploads/2020/02/Logo120.png)

There are no reviews yet.