Journal Contents

The potential of metallography in investigations of early objects made of copper and copper-based alloys

Natalia Ryndina

Pages 1-18

Investigation of early copper and copper-based alloys by optical and electron metallography enables us to answer many questions. These include revealing the modes of metalworking developed in different cultures and manufacturing centres; establishing relationships between the metalworking technology and the raw material used; analysing the raw material from the standpoint of the metallurgical processes used to produce it; investigating the structure and organization of production etc. Among the problems studied is that concerning patterns in the development of the earliest metallurgical knowledge. Over 500 microstructural analyses are discussed in this paper. They form the basis for considering manufacturing dynamics in the Near East and SE Europe: how increasingly complicated patterns can be observed from the Eneolithic to the Early Bronze Age. The interaction of primary and secondary centres of metal production is considered, based on the example of the Maikop culture of the North Caucasus.

Bole lead smelting technology and the Linch Clough (Derbyshire) bole

Lynn Willies

Pages 19-32

A technical model is presented of lead bole smelting as it is known to have been practised in late medieval and early postmedieval Derbyshire and elsewhere. It uses known parameters of fuel characteristics and reaction temperatures, together with contemporary descriptions of the technology. These are applied to the Linch Clough bole (SKI65943) excavated in 1997. A hypothesis is offered for its operation, differing from the interpretation presented by its excavators.

Understanding hammerscale: the use of high-speed film and electron microscopy

David Dungworth and Roger Wilkes

Pages 33-46

Hammerscale is the product of high-temperature oxidation of iron alloys and it is particularly associated with the forging of iron. Due to its magnetic properties hammerscale is easily recovered from archaeological contexts. While most hammerscale consists offtakes of iron oxide, a small proportion consists of spheres. This paper presents the results of the microscopic examination and chemical analysis of both flake and spheroidal hammerscale from archaeological contexts as well as material recovered during experimental forging and welding. In addition, the experimental fire-welding of iron has been recorded using high-speed digital video. This demonsti’ates that spheroidal hammerscale is produced during forge welding. The chemical analysis of the experimental hammerscale shows that it is formedfivm oxidized iron with a small but significant conti’ibution fi’om the non-metallic inclusions in the metal.

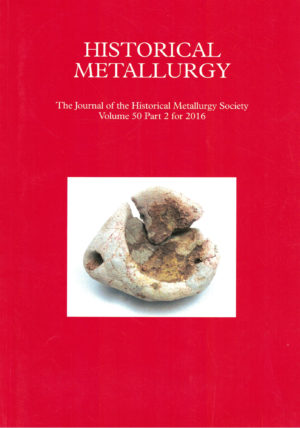

Investigation of a 16th-century gun powder chamber from the Tudor warship Mary Rose

Robert Walker and Alexzandra Hildred

Pages 47-56

Work on the gun powder (breech) section of a wrought-iron port piece has provided information about the manufacturing process, as well as the structure and properties of the iron used.

A photographic record of a water-powered wire-works at Thurgoland, Yorkshire

Ken Hawley and David Crossley

Pages 57-65

Photographs of Thurgoland Upper Wire Mill, Yorkshire, taken between 1898 and 1913, are reproduced. The text provides a commentary, and outlines of the history of the mill, and of wire drawing using wortle plates.

'Deceitful Wares' - the quality control of knives by the Searchers of the Company of Cutlers in Hallamshire

Joan Unwin

Pages 148-156

In the 1624 Act of Incorporation which established the Sheffield based Company of Cutlers in Hallamshire, there was a clause stating that all blades must have an edge of steel. The Company inspected manifactured items and policed the use of cutlers’ identifying marks. Searchers were entitled to enter workshops to seek ‘deceitful wares’—blades without steel or otherwise of poor quality. Because they also monitored the registration of the cutlers’ marks, the Searchers could idenitify manufacturers. The Company’s maintenance of restrictions led to conflicts with Sheffield cutlers who wanted to respond to economic change and to developments in iron and steel manufacture in the 18th and 19th centuries. Using the records of the Cutlers’ Company, this paper traces the Company s efforts to deal with cast-iron goods and to restrict the use of trademarks which made claims over the quality of the metal in the blade

![[Test] The Historical Metallurgy Society](https://test.historicalmetallurgy.org/wp-content/uploads/2020/02/Logo120.png)

There are no reviews yet.